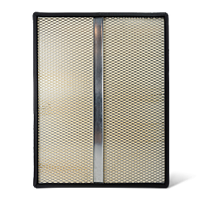

Filter Cartridges

Our wide range of filter cartridges provide efficient and cost effective contaminant removal in a wide range of gas and liquid filtration process applications across industries. Decades of industry experience coupled with our partnership approach with customers, has given us a deep understanding of filtration challenges and needs in the industry. This has helped us in creating an extensive range of filtration cartridges.

Our in house R&D, testing, engineering and manufacturing capabilities give us the flexibility to not only offer a wide range of off the shelf solutions, but also to custom build cartridges to suit specific application needs of our customers.

Jonell’s experience in cartridge development and manufacturing coupled with Nowata and JXP’s experience in manufacturing filtration housings, give us the unique ability to optimize total filtration solutions. Explore our extensive range of cartridges for gas and liquid filtration with a wide range of media options and configurations.