Water Treatment

We are committed to helping our customers to preserve the environment and conserve biodiversity by developing equipment that is specifically suited to their unique needs, whether onshore, offshore or onboard.

We achieve this with our oil water separator products and patented technologies, such as our MPak® Double-Corrugated Coalescent Plates.

Environmental Applications

Oil Water Separators

Class I Separators accordance with EN-858, effluent less than 5 ppm

Class I Separators accordance with EN-858, effluent less than 5 ppm- Access covers for easy adjustment of oil skimmers

- Epoxy coating interior and exterior

- MPak® plate packs: frame in steel and plastic hardware media is oleophilic polypropylene

- Plate packs clean in place -no need to remove from unit

- ¾”, ¼” or ½” MPak® coalescing plate spacing

- Solids collection connections built into all units

- Computerized effluent predictions for accurate sizing

- Safety closure device in the outlet

MAS Series – Oil Water Separators – Steel Construction Data Sheet

Class I Separators accordance with EN-858, effluent less than 5 ppm

Class I Separators accordance with EN-858, effluent less than 5 ppm- Outlet security device

- Access covers Class C250 accordance with EN-124

- MPak® plate packs: frame in steel and plastic hardware media is oleophilic polypropylene

- Plate packs are clean in place – no need to remove from unit

- ¾”, ¼” or ½” MPak® coalescing plate spacing

- Computerized effluent predictions for accurate sizing

MAS Series – Oil Water Separators – Concrete Construction Data Sheet

Class 1 Separators, according EN-858, effluent less than 5 ppm

Class 1 Separators, according EN-858, effluent less than 5 ppm- Safety closure device in the outlet

- MPak® plat packs

- 3/4″, 1/4″ or 1/2″ MPak® coalescing plate spacing

- Computerized effluent predictions for accurate sizing

- Solids removal connection with cover

- Vent connection

- Oil removal through manhole

MAS Series – Oil Water Separators – GFRP Construction Data Sheet

Versatile, compact, high efficiency units designed for small flow rates.

Versatile, compact, high efficiency units designed for small flow rates.

The MCP separators are great for use in removing tramp oils from machine tool coolants, floor washing or parts washing water garages, auto dealers, or other equipment service facilities.

They can even be used for (land-based) processing of oily bilge water from boats.

MCP Series – Oil Water Separators Data Sheet

New lightweight and portable housings

New lightweight and portable housings- Adjustable water outlets

- Corrosion resistant

MPP Series – Oil Water Separators – Polypropylene Data Sheet

These separators can be used for gravitational flow applications and for applications where a pump is required. Once separated out, the solids remain in the separator and are not washed out of the overflow by the next shower of rain. This makes a flow limiter unnecessary and allows the separator to also work when the flow rate is higher.

These separators can be used for gravitational flow applications and for applications where a pump is required. Once separated out, the solids remain in the separator and are not washed out of the overflow by the next shower of rain. This makes a flow limiter unnecessary and allows the separator to also work when the flow rate is higher.

Sewage Treatment Plants

Purification via biological process

Purification via biological process- No sludge generation

- No odor generation

- Access and inspection manholes in every chamber

- Meet IMO resolutions MEPC-227(64) and MEPC-159(55)

- Certified by the Maritime Coastguard Agency and the CE

STP Series Data sheet

Purification via biological process

Purification via biological process- Installation above ground

- Automatic operation driven by PLC

- No sludge generation

- No odor generation

- Access and inspection manholes

STP-HA Series Data Sheet

Purification via biological process

Purification via biological process- Installation below ground

- All control elements supplied on prefabricated steel skid to be housed in a concrete cabin

- Automatic operation driven by PLC

- No sludge generation

- No odor generation

- Access and inspection manholes

STP-HB Series Data Sheet

20′ ISO Container dimensions to facilitate the transportation and installation

20′ ISO Container dimensions to facilitate the transportation and installation- Purification via biological process

- Automatic operation driven by PLC

- No sludge generation

- No odor generation

- Access and inspection manholes in every chamber

SMS Series Data Sheet

Bilge & Sewage Water Transfer Units

Universal conic suction connection

Universal conic suction connection- 15m of 1 1/2″ non collapsible, hydrocarbons proof, suction hose

- Isolation valves at both suction and discharge

- Vandal proof cabin in stainless steel which assures no corrosion

- Electrical control panel with start/stop leds, switches and vacuostat

UTR / UTS Series Data Sheet

Marine Applications

Bilge Water Separators

Supplied ready to install, coming complete with pumps, valves and control panel

Supplied ready to install, coming complete with pumps, valves and control panel- No mobile components (with the exception of the pumps and pneumatic valves)

- Level control is fixed and has no float

CPS 3.2E + EMB for Submarines Data Sheet

Homologated for a flow rate of 0.73 m³/h (3.2 gpm)

Homologated for a flow rate of 0.73 m³/h (3.2 gpm)- Supplied ready to install, complete with pumps, valves and control panel

- No mobile components (with the exception of the pumps and pneumatic valves)

- Level control is fixed and has no float

CPS 3.2E + EMB Data Sheet

Homologated for a flow rate of 2.5 m³/h (11 gpm)

Homologated for a flow rate of 2.5 m³/h (11 gpm)- Supplied ready to install, coming complete with pumps, valves and control panel

- No mobile components (with the exception of the pumps and pneumatic valves)

- Level control is fixed and has no float

CPS 10B MKIII + EMB Data Sheet

Flow rates range goes from 0.5 m³/h (2.2 gpm) up to 10 m³/h (44 gpm)

Flow rates range goes from 0.5 m³/h (2.2 gpm) up to 10 m³/h (44 gpm)- Supplied ready to install, coming complete with pumps, valves and control panel

- No mobile components (with the exception of the pumps and pneumatic valves)

- Level control is fixed and has no float

CPS B MKIII + EBM 14x Series Data Sheet

Approved for a flow rate of 0.73 m³/h (3.2 gpm)

Approved for a flow rate of 0.73 m³/h (3.2 gpm)- Supplied ready to install, coming complete with pumps, valves and control panel

- No mobile components (with the exception of the pumps and pneumatic valves)

- Level control is fixed and has no float

CPS 3.2E + EBM 14×1 Data Sheet

Sewage Treatment Plants

Purification via biological process

Purification via biological process- No sludge generation

- No odor generation

- Access and inspection manholes in every chamber

- Meet IMO resolutions MEPC-227(64) and MEPC-159(55)

- Certified by the Maritime Coastguard Agency and the CE

STP Series Data Sheet

Meet IMO Resolutions MEPC-227(64) and MEPC-159(55)

Meet IMO Resolutions MEPC-227(64) and MEPC-159(55)- Vacuum ejectors

- Circulating pumps

- No sludge generation

- No odor generation

VTP Series Data Sheet

Oil Water Separators

Computerized effluent predictions to get an

Computerized effluent predictions to get an

accurate sizing- Optional oil skimmers and storage chamber to

separate and accumulate treated hydrocarbons - Wide range of flow rates available

Technology

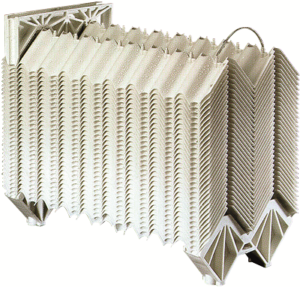

Our high-performance MPak® Coalescing Plates provide superior performance in real-world environmental clean-up.

Our high-performance MPak® Coalescing Plates provide superior performance in real-world environmental clean-up.

MPak® Coalescing Plates Data Sheet

Our MPak® plates are designed to be cleaned in place using a special cleaning wand

Our MPak® plates are designed to be cleaned in place using a special cleaning wand

MPak® Cleaning Wand Data Sheet